Laser processing system (Plotter type CO₂ laser processing machine)

Computer-controlled general-purpose laser processing machines are installed.

Plotter-based laser processing machines incorporate an X-Y plotter in a sealed enclosure,

This system uses optical transmission, in which multiple mirrors are used to direct the laser at the object.

By combining this plotter system with a compact laser oscillator,

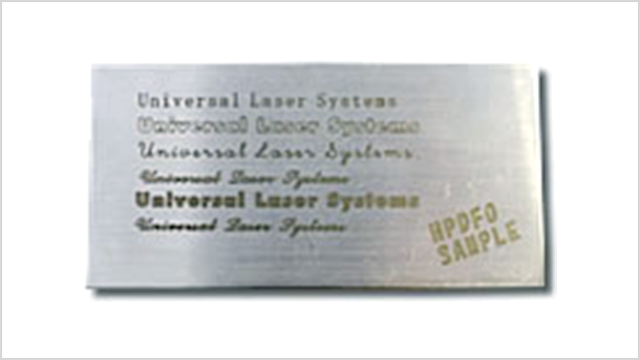

Stainless steel, titanium and other metals can be shallow-milled to enable material and size marking processes.

Equipment Features

-

POINT 01

Unlike conventional electrolyte etching methods, the goods do not corrode.

-

POINT 02

Due to the non-contact process, no physical pressure is applied to the goods.

-

POINT 03

The shallow grinding into the product makes it very visible and increases the value of the product.

Processing Flow

-

Set the product on the processing machine.

-

Computer-controlled marking.

-

Marking can be tailored to the product.

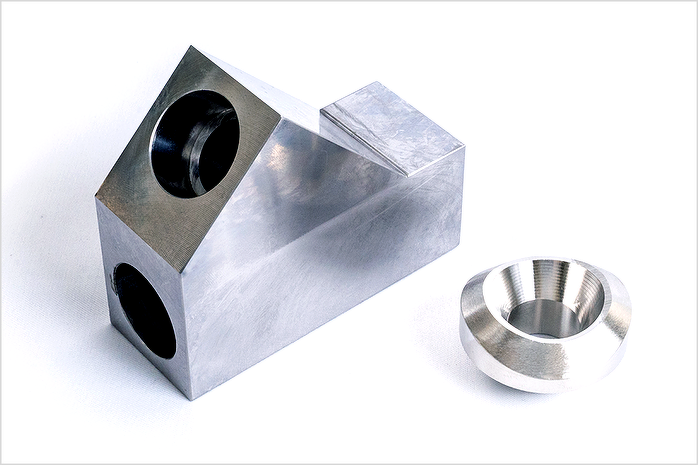

Image of the finished product

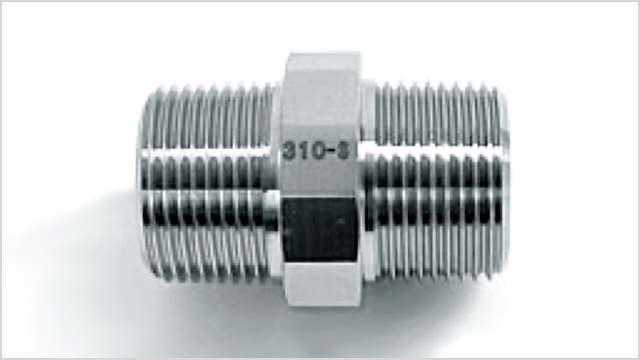

Buffing / Electropolishing

The polishing process smoothes out irregularities on the surface of the product,

In surface finishing operations carried out to remove dirt and dust from the manufacturing process,

This is an important process that greatly affects the finish of the product.

Izutsu uses buffing and electropolishing to provide the optimum finish for the product's characteristics and application.

- IZUTSUのバフ研磨*Compatible with No. 400, No. 600 and hairline.

- Buffing is a technique where a ‘polishing compound’ is applied to the stainless steel surface to create very fine scratches and shine, but if the abrasive oil adheres to the fine scratches created during the buffing process, it is very difficult to remove the dirt completely in the cleaning process.

Therefore, it is now common practice to buff only as much of the target area as possible.

However, the introduction of buffing removal washers in our company enables a high standard of cleaning, so we can also handle full surface buffing without limiting the scope of polishing. - Electropolishing at IZUTSU

- If you require a smoother, mirror-like surface on metal surfaces, we recommend a higher grade of ‘electropolishing’.

Electropolishing is a polishing method whereby metal ions are eluted from the metal surface in an electrolyte solution to smooth the surface, but also to remove fine contaminants remaining on the container surface. The smooth surface makes it difficult for dirt and other substances to settle on the surface and facilitates cleaning.

Electropolishing is essential for pharmaceutical and semiconductor manufacturers who require avoidance of contamination from surfaces and corrosion resistance.

Equipment Features

-

POINT 01

After buffing, precision cleaning is carried out to remove buffing dust, enabling use in food factories, etc.

-

POINT 02

Internal and external grinding of 6A to 600A fittings possible. Also available for hairline processing.

-

POINT 03

We provide safe and reliable products with short delivery times and low prices.

Finished image (Electropolished product)

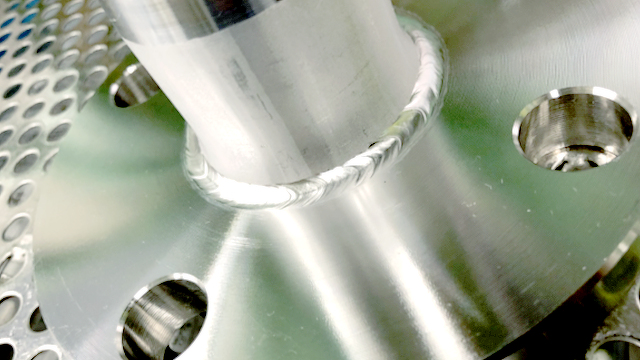

Pickling/weld tanning

When stainless steel is welded, burn marks, known as scorch marks, are left on the surface. This burnt residue is visually unsightly and causes product quality problems. For this reason, we remove burn marks one by one using a chemical method called "burn removal," which involves pickling and electropolishing.

Equipment Features

-

POINT 01

We not only provide the products that our customers require, but also offer positive added value.

-

POINT 02

More corrosion-resistant than normal products

The provision of products is made possible. -

POINT 03

No brushes are used.

Prevents quality deterioration.

Image of the finished product

Before

After

Inquiries about our products and services

Please feel free to contact us

if you have any questions or concerns about our products or order fulfillment.